Do you know that every year, thousands of household accidents are linked to gas leaks and malfunctions? This alarming statistic underscores the critical importance of ensuring your gas stove is equipped with a reliable gas stove safety valve. These devices are vital for preventing dangerous gas leaks, yet many homeowners are unaware of how they work or the maintenance they require.

In this post, we’ll explore everything you need to know about gas stove safety valves—from how they operate to why they are an essential component of your kitchen’s safety arsenal. You’ll learn about the different types of safety valves, how to install and maintain them, and the regulations that govern their use.

“The best safety device is a careful worker,” as the saying goes. By understanding and maintaining your gas stove’s safety valve, you are taking a crucial step in protecting your home and loved ones from potential hazards. Join us as we delve into the mechanics, benefits, and practical tips for keeping your stove running safely and efficiently.

How Gas Stove Safety Valves Work

Understanding how gas stove safety valves operate is crucial for any homeowner. These valves act as guardians, preventing gas leaks when the stove is not in use. Essentially, they shut off the gas flow if the flame goes out unexpectedly or if a leak is detected.

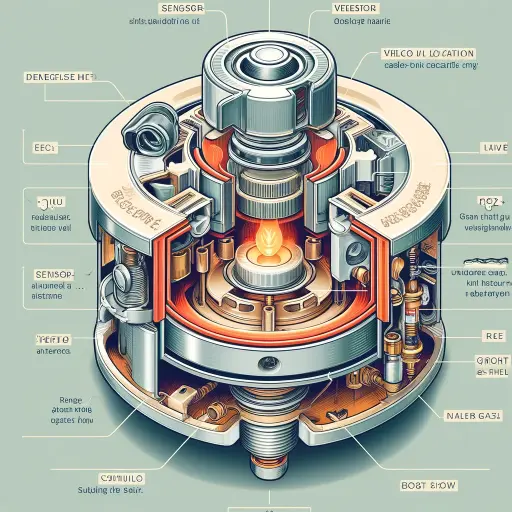

Gas stove safety valves consist of several key components:

- Sensor: Detects heat from the stove’s flame.

- Valve Body: Controls the gas flow.

- Control System: Regulates the opening and closing of the valve.

When the stove is turned on, the sensor continuously monitors the presence of a flame. If the flame extinguishes, the sensor triggers the valve body to close immediately, cutting off the gas supply and preventing any potential leak. As one safety expert put it, “Prevention is better than cure.” This mechanism exemplifies that principle by stopping hazards before they start.

Why Are Gas Stove Safety Valves Important?

Gas stove safety valves are crucial components in ensuring the safety of users and preventing accidents in the kitchen. These valves play a pivotal role in controlling the flow of gas, ensuring that it is supplied only when the burner is ignited, thereby preventing gas leaks that can lead to fires or explosions.

Critical Role in Safety

The primary function of a gas stove safety valve is to stop the flow of gas if the flame extinguishes unexpectedly. This can occur due to various reasons such as sudden drafts, liquid spillages, or the burner being accidentally turned off. Without a safety valve, gas would continue to escape, creating a highly dangerous environment ripe for ignition from a single spark or even a static discharge.

Prevention of Gas Leaks

Gas leaks are among the leading causes of household fires and explosions. Safety valves are designed to detect when there is no flame or heat from the burners and automatically shut off the gas supply. This immediate response is vital for preventing gas accumulation and the potential for catastrophic incidents. It also helps in conserving gas, thereby making the appliance more efficient.

Compliance with Safety Regulations

Most modern gas stoves come equipped with these safety valves, adhering to strict safety regulations and standards set by various safety agencies. This compliance is not just about meeting legal requirements but also about ensuring the trust and safety of consumers. The presence of a safety valve is a key feature looked for by safety-conscious buyers.

Peace of Mind

For families, especially those with young children or pets, the kitchen can often be a space of high activity and potential safety hazards. Safety valves provide peace of mind, knowing that the gas stove will not become a source of danger in the home. This assurance allows for a safer, more comfortable cooking environment.

Gas stove safety valves are indispensable safety features that protect users from the dangers of gas leaks and potential fires. Their automatic shut-off capability, compliance with safety standards, and contribution to overall kitchen safety make them a critical component in any gas stove design.

How Often Should I Check My Gas Stove Safety Valves?

Regular maintenance of gas stove safety valves is crucial for ensuring the continued safety and efficiency of your appliance. It is generally recommended to inspect these valves at least once a year. This check can be performed by a qualified technician who will test the valves to ensure they are operating correctly and efficiently. They will typically look for signs of wear, corrosion, or damage that could impair the valve’s function.

What Are the Consequences of Not Having Functioning Gas Stove Safety Valves?

Not maintaining or having dysfunctional gas stove safety valves can lead to serious consequences, affecting both safety and health.

Risk of Gas Leaks and Fires

The most immediate and dangerous consequence of a malfunctioning safety valve is the risk of gas leaks. If the valve fails to close when the flame is not present, gas will continue to flow. This can lead to gas build-up, which, if ignited, could result in a fire or explosion, posing severe risks to life and property.

Health Hazards

Continuous exposure to natural gas can be hazardous to health. Gas leaks can lead to symptoms such as headaches, dizziness, respiratory problems, and even carbon monoxide poisoning in severe cases.

Increased Costs and Legal Implications

A faulty valve can also lead to increased gas consumption, raising utility bills unnecessarily. Furthermore, ignoring the maintenance of gas appliances might violate local safety regulations, potentially leading to fines or legal challenges, especially in the event of an accident.

Damage to Property

In the event of a gas leak leading to a fire or explosion, there can be significant damage to your property and belongings, leading to costly repairs and insurance claims.

Erosion of Appliance Efficiency

Beyond safety concerns, poorly maintained valves can reduce the efficiency of your stove. This results in uneven cooking and increased fuel consumption, detracting from the overall utility and lifespan of the appliance.

Regularly checking and maintaining the safety valves on your gas stove is essential for preventing dangerous conditions in your home. Ensuring that these safety mechanisms are functional not only protects you from immediate hazards but also contributes to the long-term performance and reliability of your cooking appliances.

Steps for Testing Gas Stove Safety Valves

Testing the safety valves on your gas stove is an essential part of maintaining your appliance’s safety and efficiency. While some aspects of safety valve testing should be handled by professionals, there are a few steps you can perform at home to ensure that these critical components are functioning correctly. Here is the step by steps for testing safety valves:-

1. Visual Inspection

- Check for Obvious Signs of Wear: Begin by visually inspecting the stove and surrounding area for signs of wear or damage. Look for any visible signs of corrosion or leakage around the valve itself.

- Ensure Cleanliness: Ensure that the area around the safety valve is clean and free from debris that could obstruct the valve’s operation.

2. Flame Test

- Monitor Flame Stability: Turn on the stove burner and observe the flame. It should be stable and blue. A flickering flame or one that goes out unexpectedly might indicate a problem with the gas supply or the safety valve.

- Test Flame Extinguishment Response: Carefully extinguish the flame (e.g., by blowing it out gently). The gas supply should stop almost immediately. If the gas continues to flow (noticeable by its smell or the sound of escaping gas), this is a sign that the safety valve may be malfunctioning.

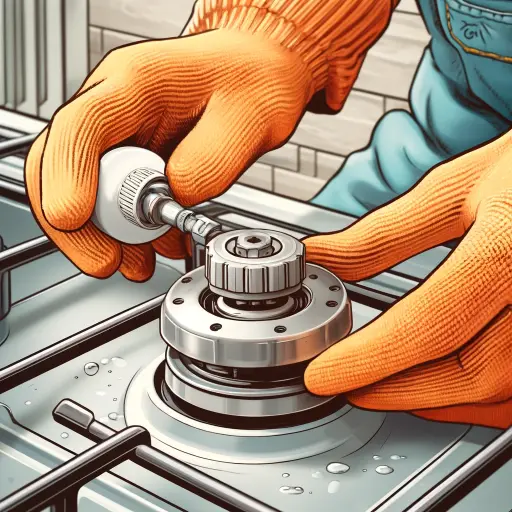

3. Soap Solution Test for Leaks

- Prepare a Soapy Solution: Mix a small amount of dish soap with water.

- Apply the Solution to the Safety Valve: Using a sponge or a small brush, apply the soapy solution to the area around the safety valve.

- Observe for Bubbles: Look for the formation of bubbles which can indicate a gas leak. No formation of bubbles usually means there are no leaks.

4. Use a Gas Leak Detector (Optional)

- Employ a Gas Detector: For a more thorough check, use a commercial gas leak detector. These devices are designed to detect the presence of gas around the stove and safety valve area.

5. Professional Inspection

- Schedule Regular Inspections: Even if all home tests pass, it is crucial to have your stove and its safety valves professionally inspected annually. A certified technician can perform more thorough tests, make any necessary adjustments, and repair or replace parts as needed.

Safety Tips

- Ensure Ventilation: Always perform these tests in a well-ventilated area to prevent gas buildup.

- Know How to Shut Off Gas: Before testing, ensure you know how to shut off the gas supply to your stove in case you need to do so quickly.

- Avoid Flames or Sparks: Do not smoke or light any flames near the stove while testing the safety valves to avoid igniting any gas that may be released.

By regularly testing the safety valves on your gas stove, you can help prevent dangerous situations such as gas leaks or fires. While simple checks can be done at home, the importance of professional inspections cannot be overstated, as they ensure your stove operates safely and efficiently.

Installation and Maintenance

Proper installation and maintenance of your gas stove safety valve are crucial to ensure it functions correctly and reliably. This section provides a detailed guide to help you manage these tasks effectively.

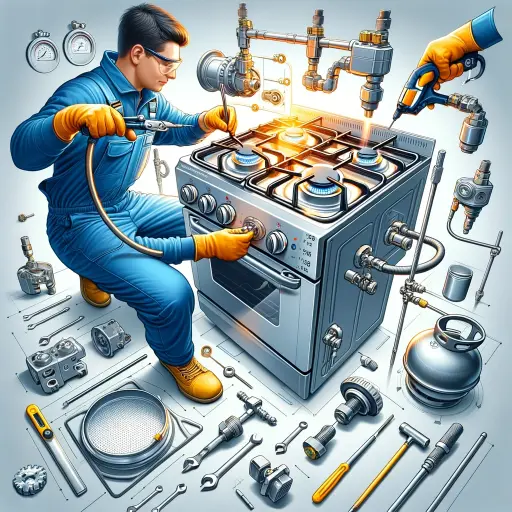

Installation of Gas Stove Safety Valve

Installing a gas stove safety valve correctly is vital for the appliance’s safety and functionality. Here’s a step-by-step approach to ensure proper installation:

- Select the Right Valve: Choose a valve that is specifically designed for your model of gas stove. Compatibility is crucial for effective function.

- Secure Connections: Make sure all connections are tight and secure. Loose connections can lead to gas leaks, which are hazardous.

- Test the System: Before using the stove regularly, conduct several tests. Simulate conditions that should trigger the valve to ensure it shuts off the gas supply as expected.

Pro Tip: Consider consulting with a professional installer who can ensure that the installation meets all safety standards and local regulations.

Maintenance of Gas Stove Safety Valve

Routine maintenance is essential for the longevity and safety of your gas stove safety valve. Here are some key maintenance tasks:

- Regular Cleaning: Keep the valve and its surrounding area clean from grease and debris, which can obstruct the valve’s operation.

- Annual Inspections: Have a professional inspect the safety valve annually to ensure it’s in good working condition.

- Immediate Repairs: If you notice any issues during regular use, such as the valve failing to shut off gas or a weak flame, address these immediately.

DIY Maintenance Tips

For those who are comfortable with basic home maintenance, here are a few DIY tips:

- Visual Checks: Regularly check for signs of wear or damage. Look for any visible signs of corrosion or leakage.

- Test the Valve: You can test the valve by turning off the stove and watching to see if the valve correctly stops the gas flow.

- Clean Regularly: Use a non-abrasive cleaner to remove dirt and grease buildup from the valve area without damaging any components.

When to Seek Professional Help

While DIY maintenance can be sufficient for minor issues, certain situations require professional expertise:

- Installation: Always have a new gas safety valve installed by a professional.

- Major Repairs: If the valve is damaged or fails repeatedly, professional repair or replacement is necessary.

- Regulatory Compliance: Ensure that any major work done on your gas systems complies with local safety regulations, often necessitating professional involvement.

Additional Resource Link: For those looking to understand more about the technical aspects or need a professional service, consider visiting Find a Certified Gas Safety Technician.

Maintaining your gas stove safety valve is not just about ensuring operational efficiency but also about safeguarding your household. Regular upkeep and proper installation can prevent potential hazards and extend the lifespan of your gas stove

To avoid gas stove safety issues, consider installing your gas stove by adhering to installation best practices.

Legal and Safety Regulations

Navigating the legal and safety regulations surrounding gas stove safety valves is essential for any homeowner. Compliance not only ensures safety but also adheres to legal standards that prevent costly fines and liabilities.

Gas stoves must meet specific safety standards, which vary by country and region. These standards are designed to ensure that every safety valve operates effectively in preventing gas leaks and accidents. Homeowners are responsible for ensuring their appliances comply with these standards. Non-compliance can lead to serious legal repercussions.

It’s crucial to understand the regulations in your area. For example, in the United States, the National Fire Protection Association (NFPA) sets guidelines for the installation and maintenance of gas appliances, including stoves. Adhering to these guidelines is not just a legal requirement; it’s a major step towards safeguarding your home against potential disasters.

Troubleshooting Common Issues of Gas Stove Safety Valve

Even with the best maintenance, common issues with gas stove safety valves can arise. Recognizing common problems and knowing how to address them quickly can prevent hazards and keep your stove in optimal working condition.

Here are some typical issues you might encounter:

- Valve Sticking: Sometimes, the valve may not close completely. This usually happens due to residue buildup.

- Sensor Failure: If the sensor fails, it might not detect the flame properly, leading to gas leaks.

- Mechanical Wear: Over time, parts of the valve may wear out and need replacing.

For troubleshooting, start with these steps:

- Clean the Valve: Remove any buildup of grease or debris.

- Check the Sensor: Ensure it’s not covered or damaged.

- Inspect for Wear: Replace worn components as needed.

Remember, if troubleshooting doesn’t resolve the issue, it’s wise to contact a professional. Handling gas appliances without proper expertise can be dangerous.

By maintaining your gas stove safety valves requires a blend of regular maintenance, adherence to regulations, and prompt troubleshooting. Taking these steps will help ensure the safety and efficiency of your gas stove, protecting your home and family.

Conclusion

In conclusion, understanding and maintaining your gas stove safety valves is essential for the safety and efficiency of your home. These valves are critical components that prevent dangerous gas leaks by automatically shutting off the gas supply if the flame goes out or a leak is detected. Regular maintenance, adherence to legal and safety regulations, and being proactive in troubleshooting common issues are key to ensuring that your safety valves function correctly at all times.

Ensure you are familiar with the safety standards specific to your region and regularly check your stove and its components for signs of wear or malfunction. Remember, prevention is always better than cure. Taking the time to understand how your gas stove safety valve works and how to maintain it can save you from potential hazards and bring peace of mind.

Always consult with a professional if you are unsure about any aspect of your gas stove’s operation or safety features. Proper care and attention to your gas stove’s safety mechanisms are not just about following regulations but protecting your home and loved ones from the risks associated with gas appliances.